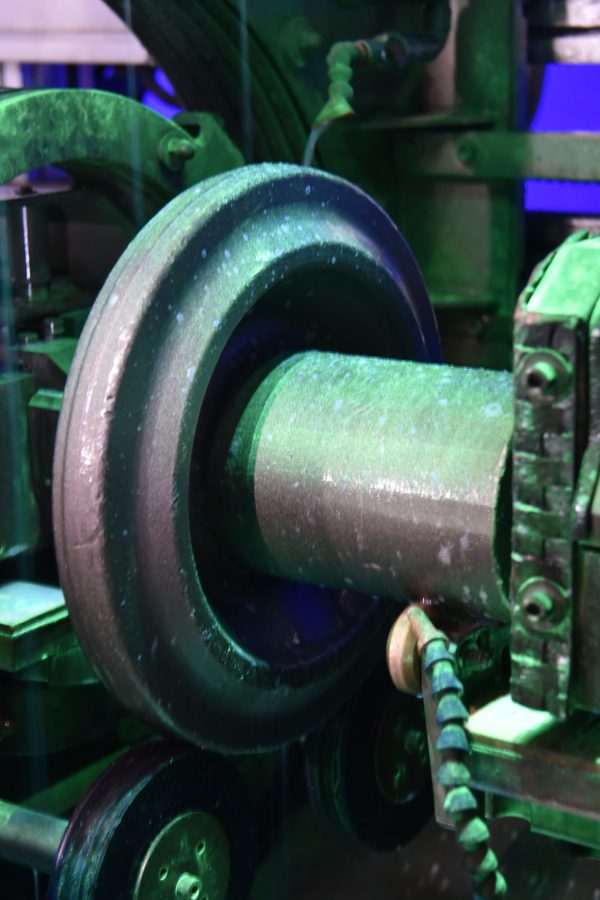

The quality and characteristics of electro-forged products — such as fatigue resistance, impact resistance and high structural uniformity — make them the ideal and exclusive product for countless uses, such as shafts, gears, pinions, tie rods and special steel screws.

Our production system operates under quality assurance according to ISO9001 and has been TUV-certified since January 1993.

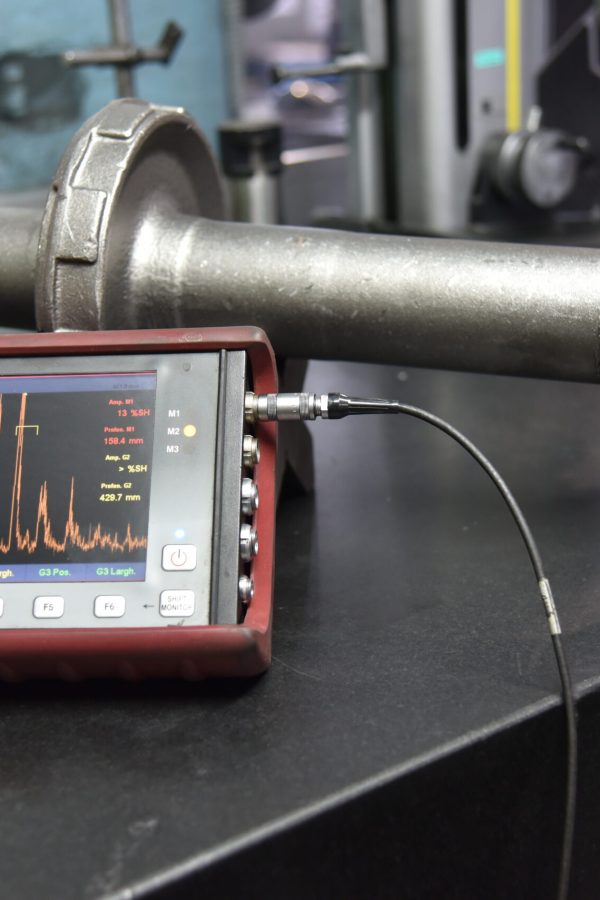

We can, of course, provide product certification with all kinds of non-destructive ultrasound, magnetic particle inspection, quantometrics and liquid penetrant tests, and mechanical and metallurgical tests.

In 2014, we achieved Quality Assurance System certification in accordance with the Pressure Equipment Directive 97/23/EC (PED).

In 2017, we achieved NORSOK certification.

Our major customers are world leaders in the fields of heavy equipment, industrial vehicles, agricultural machinery, industrial and wind power gearboxes, petrochemical valves and plants, engines, railways and the military.