A blend of art and science since 1962.

Bertoloni & Botturi Srl Officine metalmeccaniche

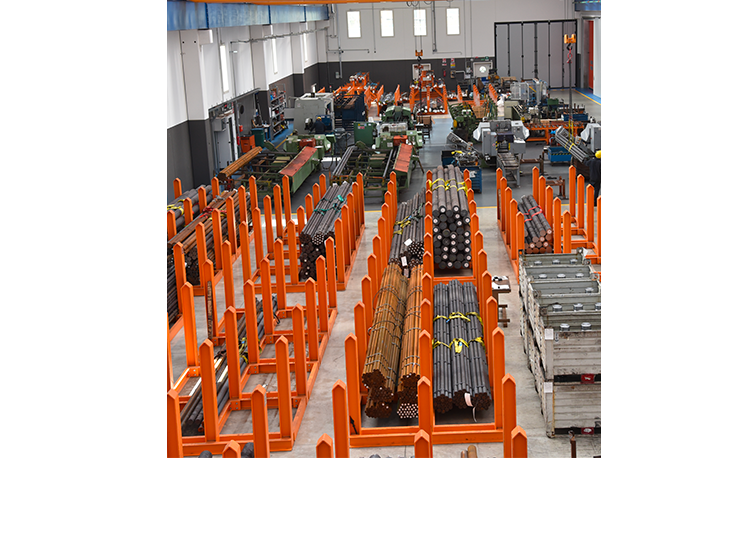

Our company has been working in the hot steel pressing sector for over 60 years.

We are located on an area of 32,000 m2, 9000 m2 of which are covered for production departments with a workforce of 75 people.

01

Hot steel pressing

Ever since the iron age, man has understood that, by bringing metal to a high temperature, it became malleable and could be shaped into elementary forms. Over the various eras, the forgers who struck hot iron with a hammer and anvil produced swords, armour and countless other articles.

Machinery and instruments

Numerous rocker arms of up to 3500 tonnes of power, combined with electric upsetting and pressing machines up to 400 kW and induction furnaces up to 1000 kW (for a total of seven work islands dedicated to vertically moulding parts), are able to meet and solve many of our clients’ increasingly sophisticated requirements, as they can deform various parts and electrically upset parts with shanks from ø 16 to ø 220, vertically moulding up to 1.3 metres and horizontally moulding up to 3 metres.

Rocker arms up to 3500 tonnes

Electric upsetting and pressing machines up to 400 kW

Induction furnaces up to 1000 kW

1 boring machine

8 CNC lathe machines

2 thread rollers

Let's look at the numbers

Bertoloni & Botturi has been in the hot steel pressing business since 1962, gaining considerable experience in machining all steels, including particularly tough materials, all stainless steels and nickel-based super alloys.

50000

+Steel tons / year

320000

Square meters of area

750

Employees

600000

+Hours worked

Our products

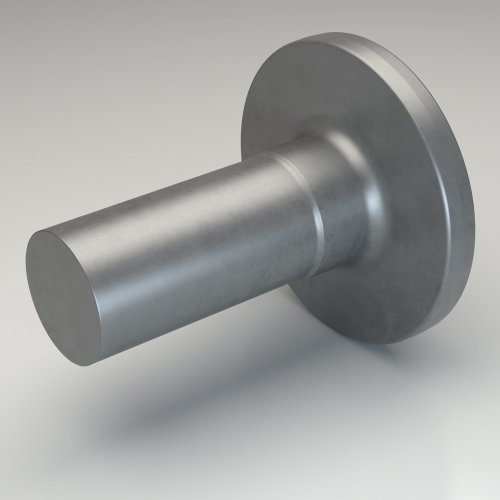

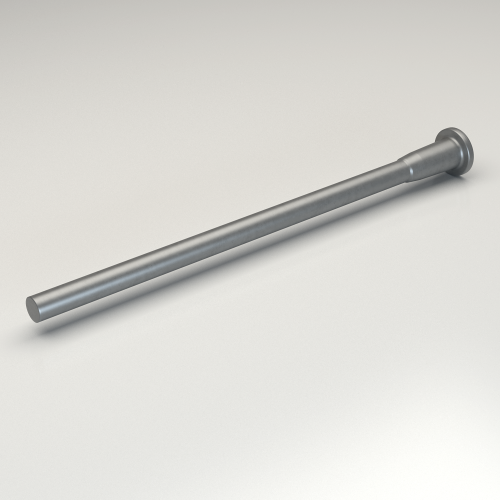

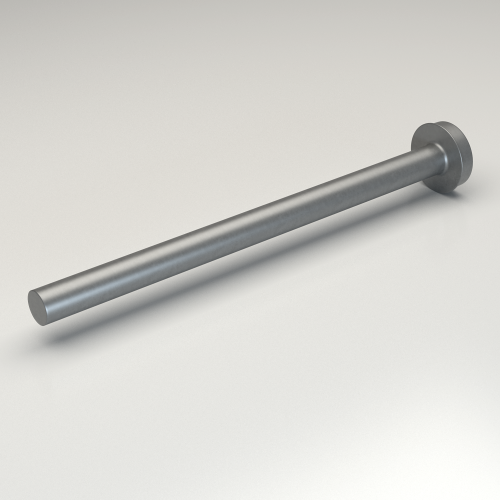

Shafts

Shafts with starting diameters from 18 to 220 mm with flange diameters up to 380 mm, and with a maximum printable length of 1100 mm

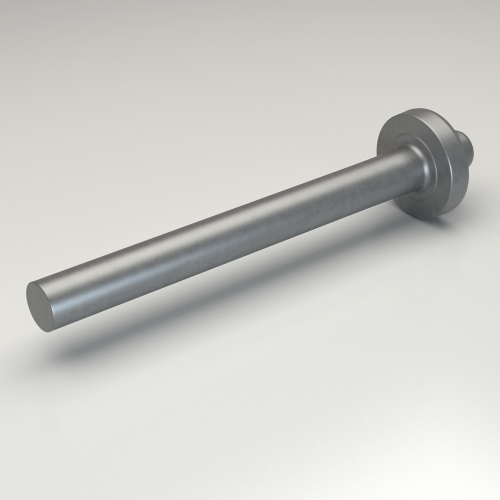

Special shatfs

Shafts with starting diameters from 18 to 90 mm with flange diameters up to 200 mm, and with a maximum printable length of 1100 mm

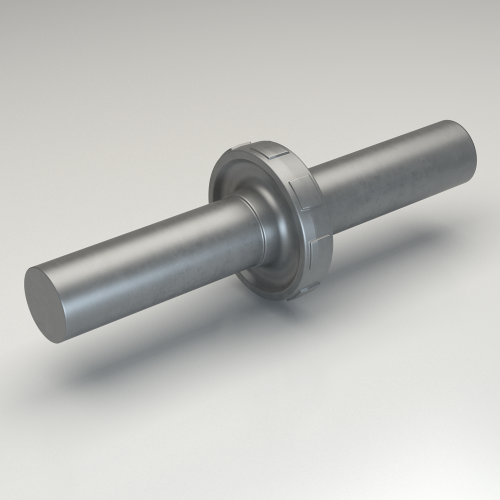

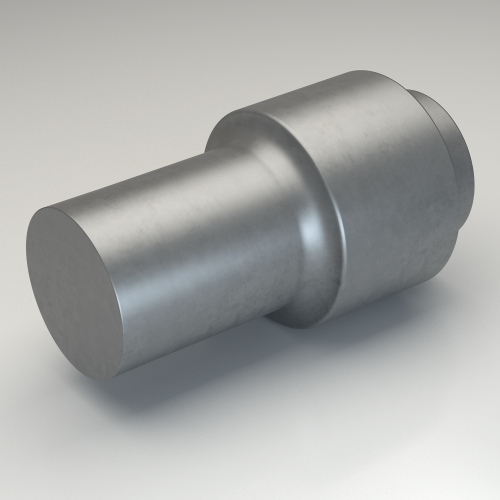

Central electric forgers

Central electric forgers with a diameter of between 20 mm and 200 mm with lengths from 70 mm to 1200 mm to client drawings and specifications.

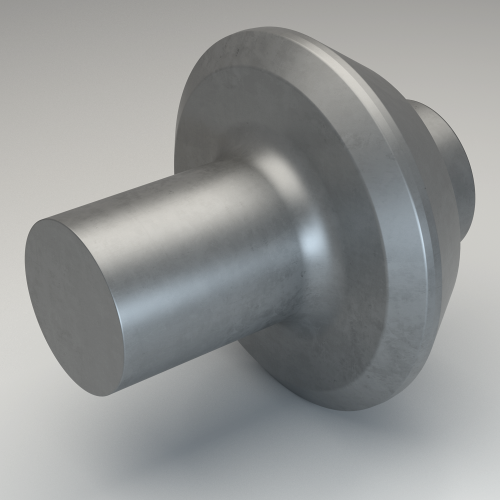

Pinions

Pinions with starting Ø from 18 to 220 mm with flange diameters up to Ø 380 mm, and with a maximum printable length of 1100 mm

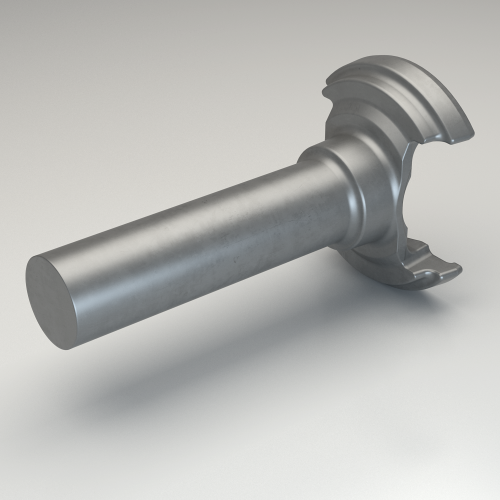

Bevel pinions

Pinions with starting Ø from 18 to 220 mm with flange diameters up to Ø 380 mm, and with a maximum printable length of 1100 mm

Direct drive

Shafts with starting Ø from 18 to 220 mm with flange diameters up to Ø 380 mm, and with a maximum printable length of 1100 mm

Axle shafts

Axle shafts with starting Ø from 18 to 220 mm with flange diameters up to Ø 380 mm, and with a maximum printable length of 1100 mm

Tie rods

Tie rods from a diameter of 25 mm to a diameter of 90 mm, with a maximum length of 1200 mm

Special screws

We can perform rolled threads and machining operations such as drilling, threading and turning.

News &Events

Visit us at the events and trade fairs we attend, and keep up to date with news from the Bertoloni & Botturi world.

Bertoloni e Botturi for the community

Bertoloni & Botturi is present in the community through its support of various sports and social associations, such as MTB Soprazzocco Mountain Biking, AC Gavardo, Atletica Gavardo 90 and Pallavolo Gavardo.